Details

DESCRIPTION:

-

The SK C Purlin is specially designed for industrial factories, warehouses, and commercial structural systems. It is manufactured from high tensile galvanized steel sheets through a cold-forming process, ensuring structural precision, stability, and long-term durability.

-

The product can be supplied in customized cut-to-length sections with pre-punched holes according to project requirements, improving on-site installation efficiency and shortening overall construction time.

-

With its high tensile strength steel and galvanized corrosion-protective surface, SK C Purlin combines lightweight properties with superior strength. It is easy to transport and can be installed on-site without the need for heavy lifting equipment.

- All products comply with major international structural standards, ensuring consistent and reliable quality.

ADVANTAGES:

-

High tensile strength

-

Galvanized corrosion-resistant coating

-

Precise dimensions and structural stability

-

Lightweight design, reducing overall structural load

-

Custom cut-to-length supply with pre-punched holes

- Fast installation, saving labor costs

Suitable for Industrial Applications:

-

Factory structural systems

-

Warehouse buildings

-

Light steel industrial structures

-

Commercial building extensions

- Steel structural cladding support systems

PRODUCT OVERVIEW

SECTIONAL PROFILE AND DIMENSIONS:

.png)

MATERIAL SPECIFICATIONS:

-

Hot dip galvanized steel to JIS G 3302 or AS1397.

-

Hi-Tensile Grade G450 Minimum Yield Stress.

-

Zinc coating mass from min 120g/m² up to 275g/m².

-

The C Purlin thickness comes in 4 types which are 1.6mm, 2.0mm, 2.5mm.

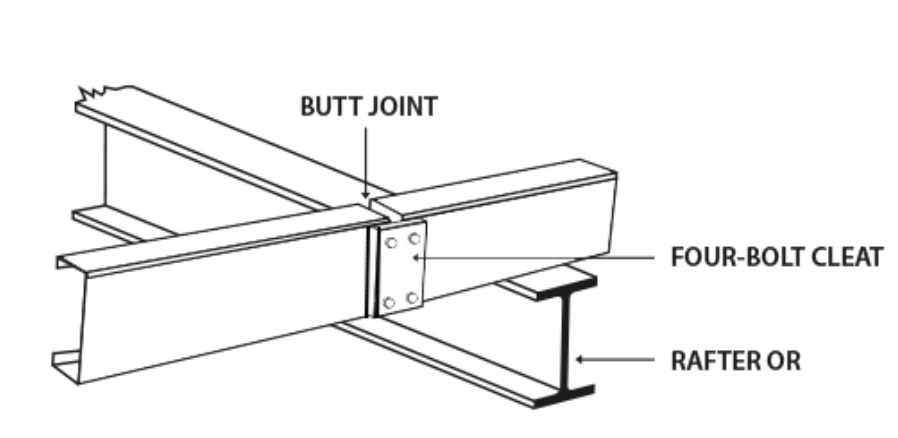

TYPICAL ARRANGEMENT OF IN-LINE C-PURLINS

View more about 0101 C Purlin on main site